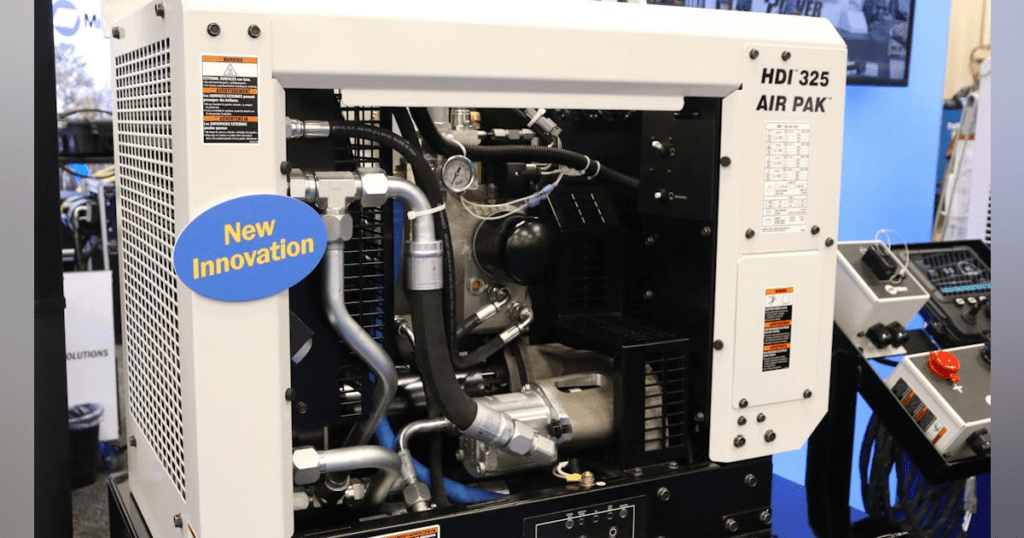

New HDI Air Pak Units Launched by Miller Electric

INDIANAPOLIS—During NTEA’s Work Truck Week, Miller Electric introduced its inaugural hydraulically driven all-in-one HDI Air Pak units.

The newly unveiled 265 and 325 systems integrate a rotary-screw compressor, an engine-driven welder, a battery charger, and an auxiliary power supply. This eliminates the necessity for separate systems, resulting in a weight reduction of up to 400 lbs and a 54% decrease in equipment footprint, when compared to the use of an engine-driven welder combined with a separate compressor. Brian Dieck, Miller’s vice president and general manager of the power systems division, stated during a press conference that, “This innovation will revolutionize efficiency and power in the work truck sector.”

A Gamechanger for Fleet Efficiency

Dieck emphasized that the HDI Air Pak series is not just a power solution; it represents a significant advancement in fleet efficiency, job site performance, and technician safety. These units are currently available for order, with Miller expecting to start shipping on May 12.

Leading Features of the HDI Air Pak

Miller’s fully integrated Air Pak units offer several industry-leading features, including:

- Onboard Compressed Air: The rotary-screw compressor supplies either 40 or 60 cfm of air at a 100% duty cycle.

- Battery Charge/Crank Assist: This feature delivers up to 150 amps of DC current for rapid charging of 12- and 24-volt batteries, including a crank assist capability that provides up to 300 amps for weak batteries.

- Auxiliary Power: Equipped with a 7,000-watt generator, it meets job site electrical demands for powering tools, lights, and more.

- Integrated Multi-Process Welding: Technicians are equipped for various welding tasks in the field with 265 or 325 amps of output at 100% duty cycle, offering various welding methods including DC stick, MIG, and TIG.

Advanced Technology for Enhanced Usability

The Auto-Set technology included in the HDI Air Pak simplifies welding parameter setups, allowing operators of all skill levels to configure settings quickly and accurately. Modular remote panels can also be established to reduce risks of slips and falls, enabling faster job completion.

Streamlined Operations and Enhanced Jobsite Conditions

A single digital user interface consolidates controls for the air compressor, battery charge/crank assist, and welding parameters, ensuring time-saving and accuracy. Maintenance is made easier with tool-free panels that provide quick access to routine service points.

Efficient and Comfortable Working Environment

Miller has integrated preventative maintenance alerts for better service scheduling, and CAN bus connectivity offers insights for fleet data management. The HDI Air Pak units enable quieter operations, which improves work environments and reduces noise fatigue. “Customers have reported that their technicians feel comfortable working beside this unit all day—something they would have previously avoided with older models,” Dieck noted.